Concrete Slab Step-by-Step

Whether you are casting concrete for foundation footings to support a simple timber structure, or for a solid slab that will form the floor of a garden building to be built from wood, the principles are exactly the same.

Of course, if the slab is to act as a foundation, it must be designed and constructed to carry the load of the brickwork, timber and any other materials used (including the roof structure). Also, the method of construction will affect the size and type of all foundations and footings.

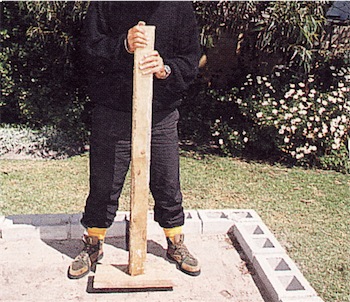

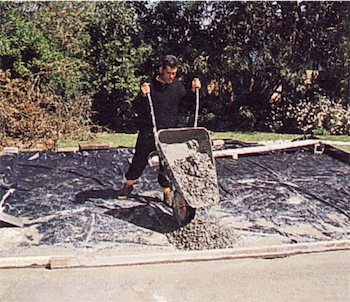

This particular slab was cast to support a timber stud structure and a 75 mm-thick slab was laid on well-compacted fill. Low-strength concrete (cement, sand and stone mixed by volume in the ratio 1:4:4) is suitable for most garden buildings, and it was this mixture that was used.

The National Building Regulations state that a straightforward foundation like this one should be constructed using concrete that has a compressive strength at 28 days of at least 10 MPa. The ratio the regulations recommend is slightly weaker than the one we used, namely 1:4:5.

SANS10400-Building Regulations South Africa SANS10400 are the Building regulations in South Africa, and both international and national standards, are fundamental to successful building and construction projects, both big and small.

SANS10400-Building Regulations South Africa SANS10400 are the Building regulations in South Africa, and both international and national standards, are fundamental to successful building and construction projects, both big and small.

so what can I do to eliminate this floor water problem,cause I need to

put a wood floor tiles.please help me…

Hi,

Someone needs to do an inspection for you and recommend a solution. I am sorry but we do not do site inspections nor do we recommend products or contractors. Contact a specialist waterproofing company in your area and ask them to have a look.

We are busy converting our roofed patio into a closed dining room. We need to lay a concrete slab between the kitchen door and the patio which is already tiled, about 1m space where there used to be decorative river stones (just with normal earth under). Do we need to lay PVC down before pouring the concrete?

Hi,

In step 5 should I nail the hoop Iron into the brick retaining walls on the inside?

Hi Matt, the hoop iron is inserted into the wet concrete/cement and then allowed to dry. You might want to bend the hoop iron 90º before you place the concrete/cement so that it is fixed fast in the foundation and will not slip straight out if it was just left flat. You will not need nails if you do this.

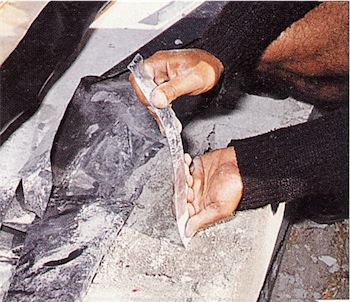

Yes any concrete slab that will be used as a living area as part of the house must have a dampproof course beneath to prevent rising damp.

hi wish to build a 2nd story on top of my current 3 garages to use a flat. I want to cast a concrete slab but not sure how to compensate for expansion on the slab? i am afraid that the expanding slab could cause cracks later on? any advise please?

H Kobus, I would suggest that you use a decking system where concrete lintols are laid across the span of the floor area and then hollow blocks are placed between the lintols. This is then topped with a layer of concrete. The result, in my experience, is a much cheaper (overall cost) and lightweight, sounproof and better insulated. There are many suppliers of this type of system, you can google or yellow pages for a company. BTW. we have put together an affordable “Concrete & Mortar Handbook” that might answer any of your questions please have a look here howtobooks.co.za/product/concrete-mortar-handbook/

Hi there.

Please help. I am planning on laying a concrete slab in my garden. 3×2.5m by 50 mm thick. I will be putting my potable pool on there which has 3000lts of water. It also needs to be very smooth. How much cement and material would I need? I’ve heard if I mix plaster mix it will be smooth..

Thanks for help in advance

What you need to do is screed the concrete with a plaster mix to ensure that it is smooth.